ARTICLE

It’s curtains for BioCord!

We often refer to BioCord as a condominium for bacteria, suspended in a free-standing aluminum frame that facilitates fast, easy installation into treatment lagoons.

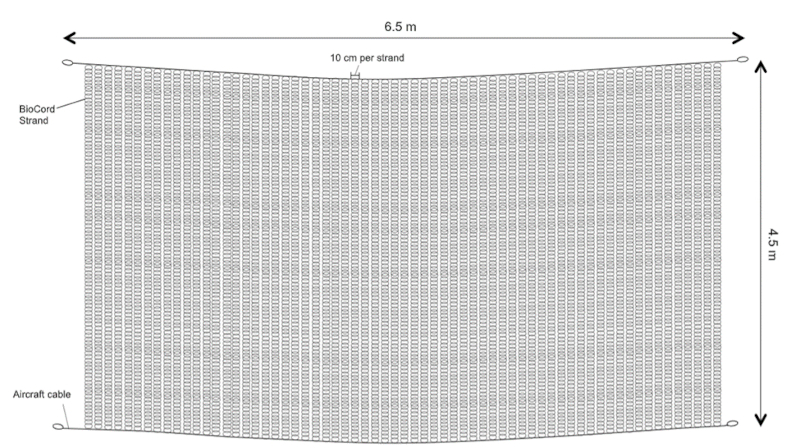

But that’s not the only way that we can configure this versatile nutrient removal system. Another option is the curtain design that enables BioCord to be installed in concrete or steel process tanks to enhance a conventional activated sludge process. These curtains are fixed within the treatment basin, eliminating concerns of carrier washout or clogging that sometimes arise with similar MBBR systems.

In this configuration, we suspend the BioCord media from stainless steel cables that span the width of a process tank. Our process specialists calculate the appropriate amount of BioCord that should be added to the process tank to achieve the target removal rates for ammonia, total nitrogen and BOD.

Once installed, the BioCord media provides a massive surface area on which nutrient-removing bacteria can attach and form a highly efficient and highly concentrated biofilm. The BioCord media is made up of a blend of durable, inert materials, meaning that no replacement of the fibres are required as long as they are not physically damaged. This approach can significantly increase plant performance and capacity within the existing footprint, eliminating the cost of additional process tanks and related equipment.

BioCord curtain systems also require little energy to operate. Unlike similar technologies that use individual carriers to support biofilm growth, BioCord Curtains are fixed in place, and do not require additional energy to keep the media circulating and/or in suspension.

In some cases, the existing aeration system may provide sufficient oxygen to maintain BioCord and the existing activated sludge process. This may If not, the BioCord compressor-powered aeration system can achieve high oxygen transfer to the biofilm for a fraction of the capital and operating cost of typical blower-powered systems.