CASE STUDY

BioCord® pilot system proves mettle for cold-weather ammonia removal

The challenge:

Affordably improving ammonia removal without expanding plant footprint

Onsite wastewater lagoons at a petrochemical manufacturing plant in Western Canada were experiencing difficulty in meeting the ammonia discharge limit during cold-weather conditions.

The three-cell lagoon system provides pretreatment of the facility’s sanitary and process wastewater before the effluent is released to the municipal sewer. But during the winter months, the system struggles to achieve the discharge limit set by the city.

Low temperature and high BOD are often responsible for impeding the ability of a wastewater lagoon to remove ammonia and can result in noncompliance. Unfortunately, the problem was compounded when operators learned that more stringent discharge regulations were coming.

Operators took proactive steps to install aeration/mixing and baffle curtains in the third pond in an attempt to improve performance, but these measures did not achieve the anticipated results.

The petrochemical plant needed a simple, costeffective way to reliably achieve high ammonia removal in winter conditions.

The solution:

Plug-and-play BioCord system quickly installed

A Bishop BioCord® Reactor pilot system was installed to evaluate its ability to improve BOD and ammonia removal in Pond 2 of the facility.

BioCord Reactors are like condominiums for bacteria that dramatically increase biological nutrient removal and require little energy or operator oversight.

The BioCord media provides a massive surface area for a robust biofilm to form and thrive.

The containerized plug-and-play system arrived fully assembled and was quickly installed with only four connections for influent, effluent, overflow and power.

Effluent from Pond 1 was directed to a 3,400L tank in the side stream system. Both Pond 2 and the BioCord system received the same influent for the duration of the pilot test.

After about six weeks of operation, a second 3,400 L BioCord tank, was added to the pilot system to cope with higher than anticipated organic loading.

BioCord’s Cold Weather Ammonia Removal Success

A simple, low-energy process achieves high ammonia and BOD removal

Throughout the 14-week pilot test, the BioCord system performed significantly better than Pond 2 for reducing ammonia concentrations and other key treatment parameters such as cBOD, TSS and COD.

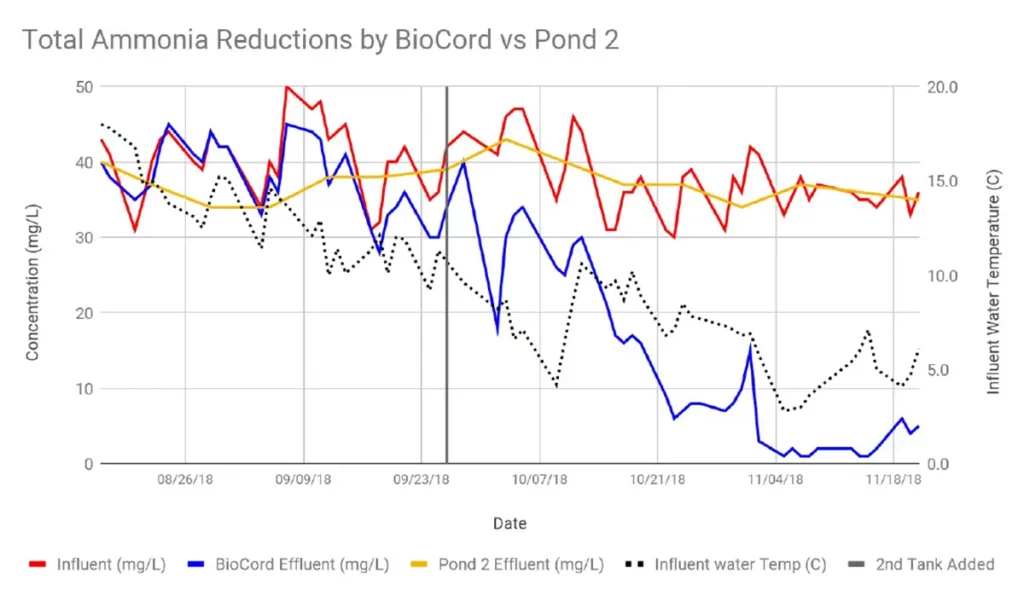

Influent and effluent ammonia concentrations in the BioCord Reactor pilot system. Ammonia concentrations from the effluent of Pond 2 are also shown. Influent wastewater was drawn from the outlet of Cell 1 of the facility’s 3-pond system. Water temperatures are plotted on the secondary axis.

Even when the temperature of the wastewater fell as low as 2.8⁰C, BioCord was able to remove 97% of the ammonia. On average, the BioCord Reactor pilot system was able to reduce ammonia concentration in treated effluent to about 13 mg/L, vs. influent concentration of about 38 mg/L.

By comparison, Pond 2 was only able to achieve an average of 2% ammonia reduction during cold conditions, reducing the concentration from an average of 38 mg/L to 37 mg/L, well above the site’s regulated discharge limit of 30 mg/L.

Similarly, the BioCord Reactors significantly reduced cBOD from influent levels that were nearly as high as 75 mg/L to less than 10 mg/L in treated effluent.

Achieving sufficient cBOD removal is an important first step in ammonia reduction since BOD-reducing bacteria and nitrifiers both require oxygen to thrive and treat wastewater.

Full-scale BioCord system keeps costs low and avoids footprint expansion

Unlike alternative approaches that require additional tanks and energy-intensive blowers, a full-scale BioCord system is installed directly into the treatment lagoon, helping to minimize capital costs and eliminating the need to expand plant footprint.

This design, along with low-energy compressors, rather than costly blowers enables a BioCord system to consume about 50% less energy than an MBBR system designed to achieve the same level of nutrient removal. The compressors, combined with an integrated aeration diffuser, provide an opti-mized level of oxygen and mixing to develop a robust, highly efficient biofilm.

A full-scale BioCord system is installed directly into a wastewater lagoon, which minimizes capital cost and avoids expansion of the plant footprint. Baffle curtains enable the most intensive arrangement of BioCord Reactors by forming a raceway that maximizes contact between the biofilm and the wastewater.