ARTICLE

Is your lagoon suffering from washout?

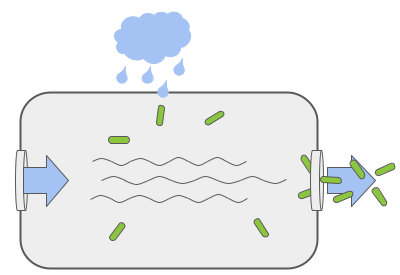

Every wastewater plant can experience washout—a condition where high hydraulic loading causes microorganisms to be flushed out of a treatment cell at a faster rate than they can be replenished. It happens during periods of peak sanitary flow or during wet weather and its occurrence may be on the rise as we experience more frequent and extreme precipitation due to climate change. Inflow and infiltration can compound the problem adding more water to the sanitary system and further diluting the treatment process.

Diagnosing washout at your plant

Reducing retention times in treatment cells is the most common approach to enable lagoons to accommodate high hydraulic loading and avoid the need to bypass one or all of the treatment steps. But due to the faster flow, operators may see a decline in the treated effluent quality.

The telling sign of washout is that even after the influent flow returns to normal levels, the quality of treated effluent may continue to suffer days or even weeks after the event. This lag in performance indicates that a significant portion of the microbiological population has been lost to washout and the remainder is unable to provide adequate nutrient removal. The condition will continue until the microbiological population is re-established to the optimum level.

In the warmer months, the microbial population can rebound fairly quickly. But since temperature plays a major role in the growth rate of nitrifying and heterotrophic bacteria, a washout in the fall or winter can have serious long-term consequences to lagoon performance. If temperatures drop after a washout event, the microbial population may not fully recover until the spring, which means the plant could have to operate at reduced capacity or face compliance issues through the cold-weather period.

Peak sanitary flow and wet weather cause washout of suspended bacteria and compromise treatment performance.

Build a better home for bacteria

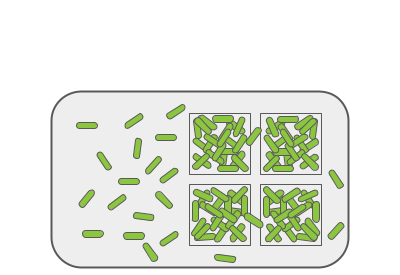

BioCord® Reactors are a simple, low-energy, fixed-film treatment technology that can help prevent the washout problem. BioCord is like a condominium for bacteria that adds a massive amount of surface area to a lagoon cell and provides the ideal environment for preferred, naturally occurring bacteria to thrive. Even though suspended bacteria may be lost to washout, BioCord retains its productive biofilm. The biofilm continues providing treatment, while also helping the lagoon return to optimum performance following the high-flow event.

BioCord reactors are resistant to washout, so WWTPs maintain performance during high hydraulic loading and quickly re-establish suspended bacteria population.

BioCord Reactors can be installed directly into a treatment lagoon. They quickly establish a robust, stable biofilm that is resistant to washout and enhances plant performance in cold-weather conditions.

BioCord boosts cold-weather performance too

The BioCord Reactor system is also designed to provide reliable removal of ammonia and BOD in cold weather. One way BioCord does that is by increasing the inventory of bacteria needed for wastewater treatment far beyond the capabilities of ordinary suspended sludge systems. More bacteria, means more nitrification and BOD removal.

BioCord Reactors can be installed directly into a treatment lagoon. They quickly establish a robust, stable biofilm that is resistant to washout and enhances plant performance in cold-weather conditions.

Another way is that the BioCord biofilm develops in layers, which helps insulate inner microorganisms from cold water. This enables nitrifiers to maintain ammonia removal and respond to loading rates even when the wastewater temperature is as low as 0.5°C. BioCord biofilm has repeatedly demonstrated its ability to tolerate and thrive in cold conditions with observable changes in biofilm growth and greater ammonia removal rates as loading increases.