CASE STUDY

City of Vaughan – Geotube® technology For storm pond cleaning

The challenge:

The City of Vaughan required sediment removal of three separate storm water management ponds. The city wanted to have a minimal impact on the surrounded communities and watercourses.

Bishop Water provided a service that did not require draining the pond or taking it off line at any time during the process.

The solution:

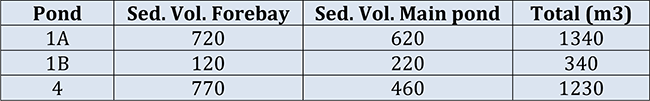

Bishop Water was chosen to provide hydraulic dredging and sediment dewatering using Geotube containers. With an estimated sediment amount of 3,100 cubic meters, Bishop Water provided a service that did not require draining the pond or taking it off line at any time during the process.

The Geotube solution was provided with very low impact to the surrounding environment as there was no construction vehicle traffic, reduced carbon footprint, and minimal impact on receiving water bodies since flow volumes and turbidity levels were unaffected throughout the project.

The process:

A remote controlled dredge with towlines was deployed into the pond. The dredge was guided by a cable in a grid pattern to ensure no areas of the pond were missed.

The dredge pumped a slurry of sediment and water through a 6” diameter hose from the pond, passing through a polymer injection system and then into the Geotube® where the dewatering process took place. The sediment volume in situ totaled approximately 3,100 cubic meters at between 9% and 22% solids. As expected, higher percent solids content was found in the pond forebays.

A powdered anionic polymer was used in this application. State of the art injection technology allowed for optimization of the polymer used, a critical component to the project’s success.

The Geotube® continued to dewater the sediment after the pumping was completed.

The Bishop Solids Management Solution used a two-layer, stacked arrangement of Geotube dewatering containers to minimize the footprint and cost of the dewatering cell.

Generally the longer the Geotube® is allowed to sit, the more dewatering that takes place. After approximately one month, the tubes are ready to be opened up and the sediment removed. The Geotubes were cut open and the consolidated sediment removed and hauled to a disposal site.