Simplify Polymer System Maintenance with Bishop VEPAS

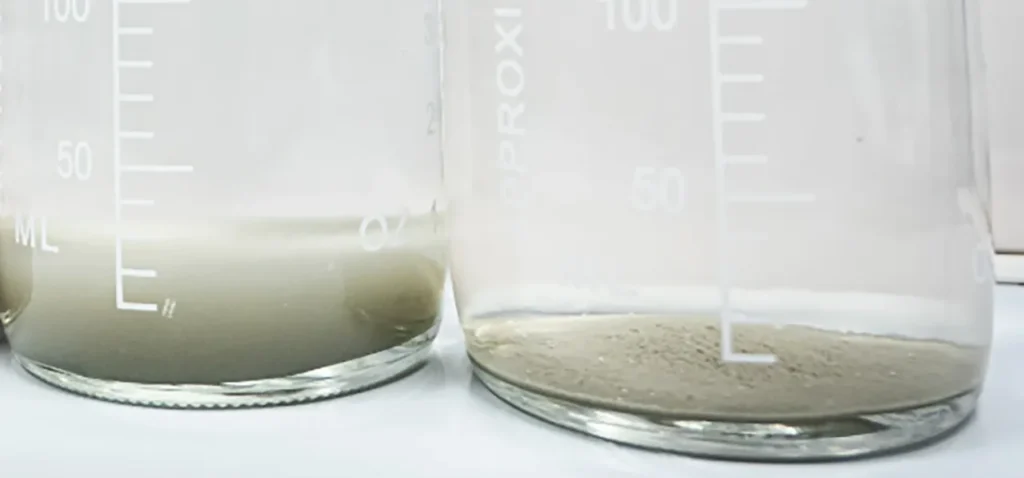

When it comes to polymer system maintenance, traditional mechanical setups can be a real headache, bogged down by complex components like mixers, aging tanks, and intricate piping that demand hours of cleaning and upkeep. Bishop Water’s Venturi Emulsified Polymer Activation System (VEPAS) changes the game by streamlining maintenance into a fast, efficient process. By eliminating those cumbersome parts, VEPAS cuts down maintenance time dramatically—transforming a task that once took hours into one that’s completed in mere minutes. This innovative design not only saves effort but also reduces the risk of clogs, ensuring your system stays in top shape for sludge dewatering or other wastewater treatment needs.

Curious about how this works in practice? Watch our detailed video to explore the straightforward steps of polymer maintenance with VEPAS. You’ll see firsthand how our team flushes the system with ease, prevents blockages, and prepares it for its next use—all without the hassle of conventional equipment. Whether you’re managing a municipal lagoon or an industrial treatment plant, VEPAS offers a low-maintenance, high-performance solution that keeps your operations running smoothly. Check out the video now and discover why VEPAS is the smart choice for effortless system maintenance.