Stacking Geotubes saves space, but how high can we go?

Bishop Water’s stacking Geotube technique maximizes space and efficiency, offering a sustainable solution for managing and dewatering solids in wastewater and industrial applications.

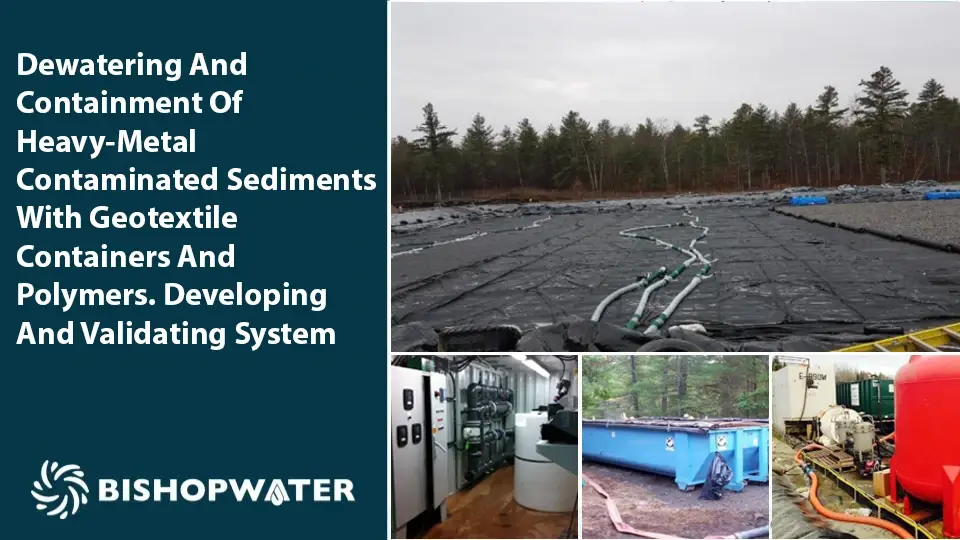

Dewatering and Containment of Heavy-Metal Contaminated Sediments with Geotextile Containers and Polymers. Developing and Validating System Performance and Design

A former mine site in Eastern Canada utilized a hydraulic process involving dredging, geotextile containment, and polymer conditioning to efficiently remove and dewater contaminated sediments, reducing environmental impact and enabling site reclamation.

Gravity-based sediment dewatering reduces disposal volume and hauling for waterway remediation project

Learn how Bishop Water’s gravity-based sediment dewatering system helped the City of Hamilton efficiently remove and dewater 140,000 m³ of sediment from Chedoke Creek, reducing disposal volume and hauling requirements for a major environmental remediation project.

Sinking in sludge: How to identify excessive sludge accumulation

Bishop Water is partnering with Western University in a new project with BioCord Reactors that aims to further optimize wastewater treatment efficiency, reduce energy consumption, and lower greenhouse gas emissions.

Defer sludge disposal costs with Geotube® containment

eotube containers, part of the Bishop Solids Management Solution, provide a solution, offering not only a simple way to collect and dewater sludge, but also to store it for an extended period.

Quietly effective: Dewatering stormwater pond sediments with geotextiles and gravity

For those entrusted with the care and maintenance of stormwater management ponds, removing accumulated sediments is no small matter.

Mastering lagoon desludging projects: A proactive approach

Removing accumulated sludge from a lagoon system is a fast, cost-effective way to restore treatment capacity and performance. But, a successful lagoon desludging project requires thoughtful planning and careful execution to sidestep potential pitfalls that could escalate costs and slow down production.

Geotube® vs. belt press. Which one wins for sludge dewatering?

Gravity or pressure—which is more efficient when dewatering wastewater sludge? Both are proven methods to remove water from slurry and produce a cake that can be handled for disposal or land application.

What’s that smell? Diagnosing springtime lagoon odours.

non-aerated lagoons, can experience benthal feedback—a process where the turbulence of the warming water stirs up the sludge blanket and releases hydrogen sulfide gas along with nutrients that have accumulated in the settled sludge.

What to do when your lagoon’s effluent TSS is higher than the influent TSS

Learn how Bishop Water tackles lagoon TSS management when effluent TSS exceeds influent, with effective solids solutions.