The advantages of low-energy, high-performance Geotube dewatering for biosolids management

Spinning, squeezing, solar drying, there are many ways to dewater sludge from treatment plants and produce stabilized biosolids that are ready for land application or disposal. Selecting the best approach often considers several factors, including the speed at which dewatering must be completed, the space that’s available at the treatment plant to accommodate the process, and capital and operating costs.

Operators traded wheelbarrows for Bishop Solids Management solution to reduce time and labour in sludge handling

It used to take almost a month to dewater the same volume of sludge that is now done in less than a day at the Meteghan Sewer Treatment Plant (STP) in the Municipality of Clare, Nova Scotia.

How a polymer dosing system can make or break your sludge dewatering process.

Polymer is the secret ingredient for maximizing dewatering and achieving high quality filtrate from the Geotube® containers in our Bishop Solids Management Solution. But selecting the right polymer is not enough to get the best results.

Simple residuals management system saves $6 million for water treatment plant

See how a residuals management system saved $6M for a water treatment plant with Bishop Water’s simple, cost-effective solution.

Bishop Solids Management Solution for dewatering and reuse of excess soil

Eliminate the need to truck muddy construction slurry from hydrovac trucks to distant sites for dewatering or disposal. The Bishop Solids Management Solution provides an easy-to-use, affordable process for onsite collection and dewatering of excess soil excavated during urban construction activities.

Simple, cost-effective sludge management in the far north

Sludge management is challenging for the remote Hamlet of Pangnirtung, Nunavut on Baffin Island.

City of London relies on strength and durability of Geotube® containers for award-winning ash dewatering solution

After dewatering thousands of tonnes of ash, using dozens of Geotube® containers, the Greenway Wastewater Treatment Plant (WWTP) in London, Ontario reports that the five-year-old system continues to “exceed expectations” for reliability and performance.

Bishop Solids Management Solution — Dewatering for all occasions

We’ve dewatered a lot of stuff over the years.

Everything from ordinary wastewater sludge and excess soil from construction sites, to noxious slurries containing really smelly organics, industrial process wastewater, and even low-level radioactive materials.

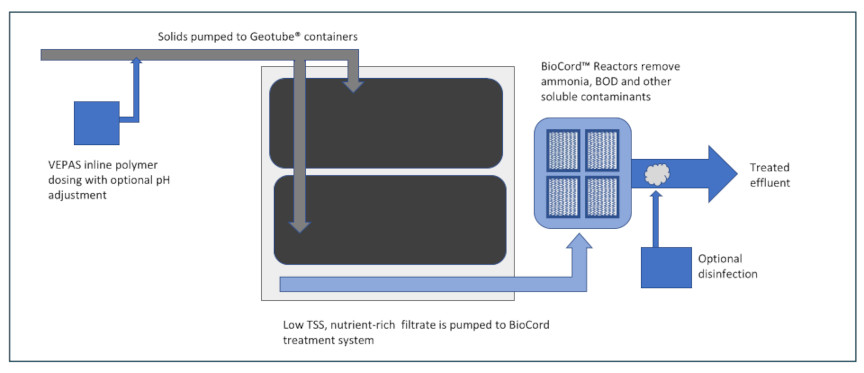

How to eliminate sewer surcharges with a simple, low-energy system

Pre-treatment of high-strength wastewater before discharging it to a municipal sewer can be challenging, especially if high levels of BOD, TSS and ammonia are present.

Potato processor treats and reuses wash water with simple, affordable dewatering system

High-TSS wash water can cause storage ponds to fill quickly with sediment and increases the risk of overflow. Learn how an Ontario-based grower used the Bishop Solids Management Solution to create a simple system that collects and consolidates solids while producing low-TSS filtrate that can be reused in the washing process.