ARTICLE

Cheese producer switches to ClariPhos™ coagulant to improve phosphorus removal, eliminate tertiary filtration

Phosphorus removal has never been better for an Ontario cheese producer after switching to ClariPhos™ Rare Earth Coagulant for its onsite membrane bioreactor (MBR) system. Operators began using ClariPhos in 2019 after experiencing inconsistent results with aluminum sulphate (alum) to achieve a phosphorus limit of less than 1 mg/L.

When the plant was commissioned several years ago, alum was initially added directly to the MBR to precipitate phosphorus in the process tank; however, this resulted in excess foaming, significant swings in pH and frequent upsets to the biological process. A tertiary filtration system was installed at a cost well into six figures, and though the system did alleviate the issues and consistently achieve the target phosphorus limit most of the time, it also significantly increased operating and maintenance costs. The operations team continued searching for a simple, cost-effective solution.

Fast and easy switch to ClariPhos

Bench testing with ClariPhos showed promising results and in the spring of 2019 the plant began full-scale testing. The transition was simple since ClariPhos uses the same chemical feed equipment as alum. Operators simply replaced the tote, flushed the line and set the new, much lower dose rate for ClariPhos. Since one of the objectives was to eliminate the tertiary filtration system, the team decided to add ClariPhos directly to the MBR, despite the problems that were experienced with the alum.

Within a few days, the benefits of ClariPhos began to emerge for the operators:

- Foaming and pH swings were no longer occurring. ClariPhos is about 100 times less acidic than aluminum sulphate, which combined with the lower dose, enables overall system pH to remain close to neutral and avoid process upset.

- Caustic (NaOH) was no longer needed to balance the acidity of alum, saving the plant thousands of dollars and eliminating the need to store and handle this hazardous chemical.

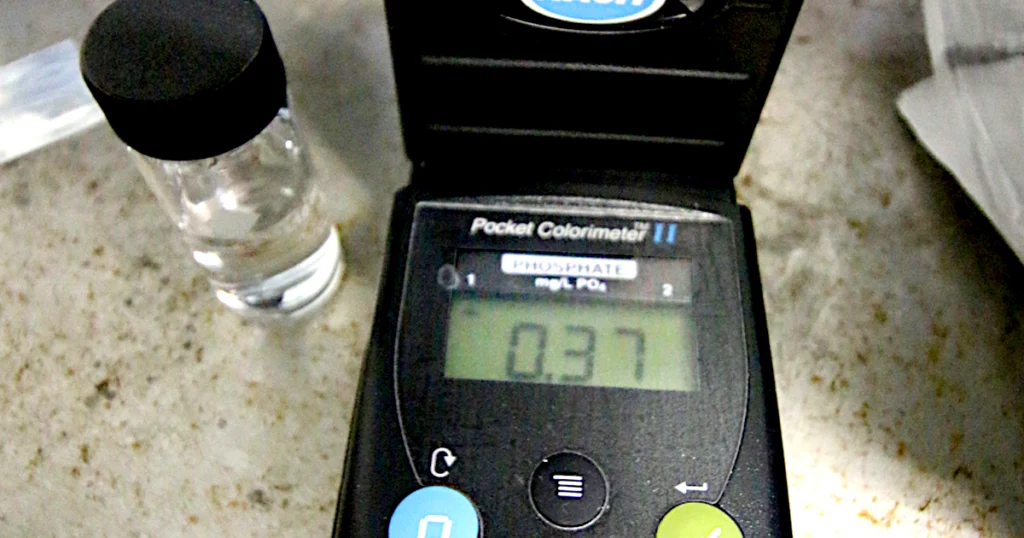

- Consistent treatment performance and compliance with the phosphorus limit of < 1 mg/L.

- Tertiary filtration is no longer needed, eliminating costs of operation and of handling of the secondary sludge wasting process.

- Reduced coagulant consumption. The ClariPhos dose at the site is consistently four to six times lower than aluminum sulphate.

- Improved operator safety. ClariPhos is about 100 times less acidic than alternatives, performs at a lower dose rate and often requires no pH adjustment. This means operators can dramatically reduce the volume of chemicals that are stored and handled at a plant.

Watch our video to see faster settling rate and lower sludge production for ClariPhos vs. conventional aluminum- and iron-based alternatives.