ARTICLE

How to remove more phosphorus with less coagulant

How can a wastewater treatment plant improve phosphorus removal while reducing the amount of coagulant it’s using? The answer: switch to a coagulant that forms a strong, preferential bond with phosphorus.

Here’s why that works.

Conventional aluminum- or iron-based coagulants don’t form a strong bond with phosphorus. Instead, they first form metal oxide intermediates, which is followed by phosphate adsorption to the metal oxide. This is a relatively weak bond that is reversible and non-specific to phosphorus, which means that more coagulant is needed to achieve low effluent phosphorus concentrations.

Conventional aluminum- or iron-based coagulants don’t form a strong bond with phosphorus. Instead, they first form metal oxide intermediates, which is followed by phosphate adsorption to the metal oxide. This is a relatively weak bond that is reversible and non-specific to phosphorus, which means that more coagulant is needed to achieve low effluent phosphorus concentrations.

Bishop Water’s ClariPhos® is made with the rare earth elements cerium and lanthanum. These elements have a very high affinity for phosphorus and quickly form rhabdophane, a dense and insoluble precipitate. Rhabdophane is a stable mineral that naturally occurs and will not re-solubilize and release phosphorus back into the treated effluent.

High affinity and strong bonds reduce coagulant dosing

Since ClariPhos has a strong tendency to combine with phosphorus it is far more efficient than conventional coagulants, so less is needed to remove an equivalent amount of phosphorus. Plants that have switched to ClariPhos report dose rates that are up to eight times lower than those of conventional coagulants.

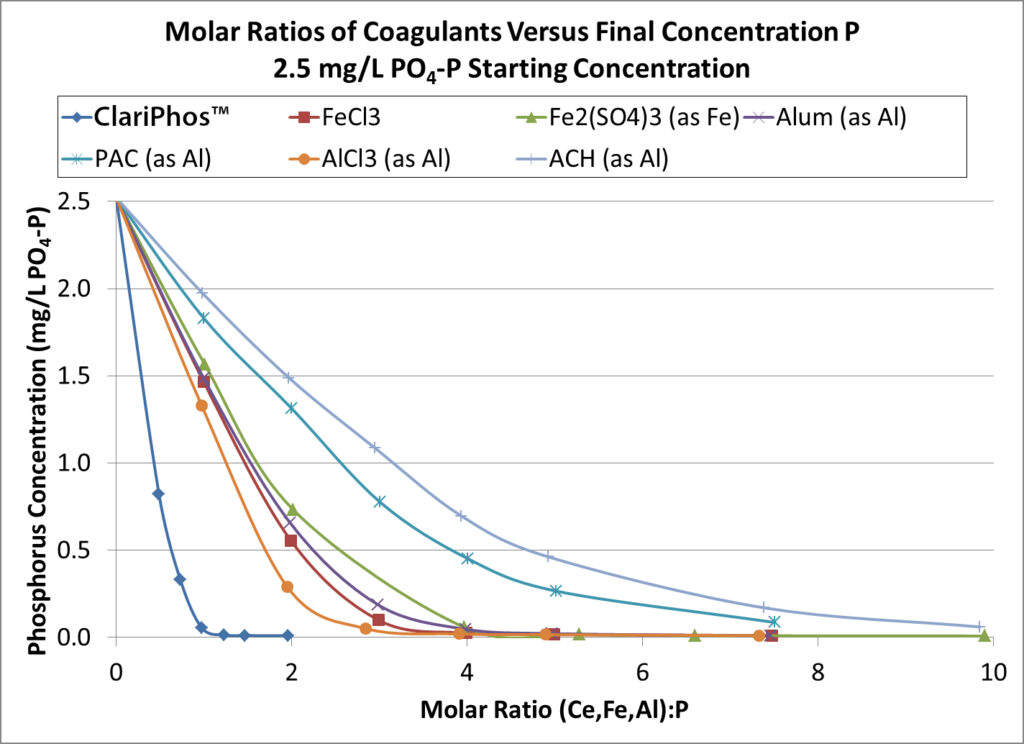

The graph below, compares the dose rates (in moles) of ClariPhos against several aluminum- and iron-based coagulants to achieve a range of phosphorus targets. As the phosphorus targets drop, the dose rates for the aluminum- and iron-based coagulants increase significantly. To achieve 0.1 mg/L, these coagulants the dose rates range from 3:1 to almost 8:1.

ClariPhos, by comparison, can achieve 0.1 mg/L of phosphorus in treated effluent at a molar dose rate that is about 1:1. That not only reduces chemical consumption, it can dramatically reduce sludge production too. Wastewater plant operators have seen sludge volumes decrease by as much as 50% with improvements in sludge dewaterability of up to 40%.