ARTICLE

Ontario WWTP eliminates pH adjustment after switch to ClariPhos® coagulant

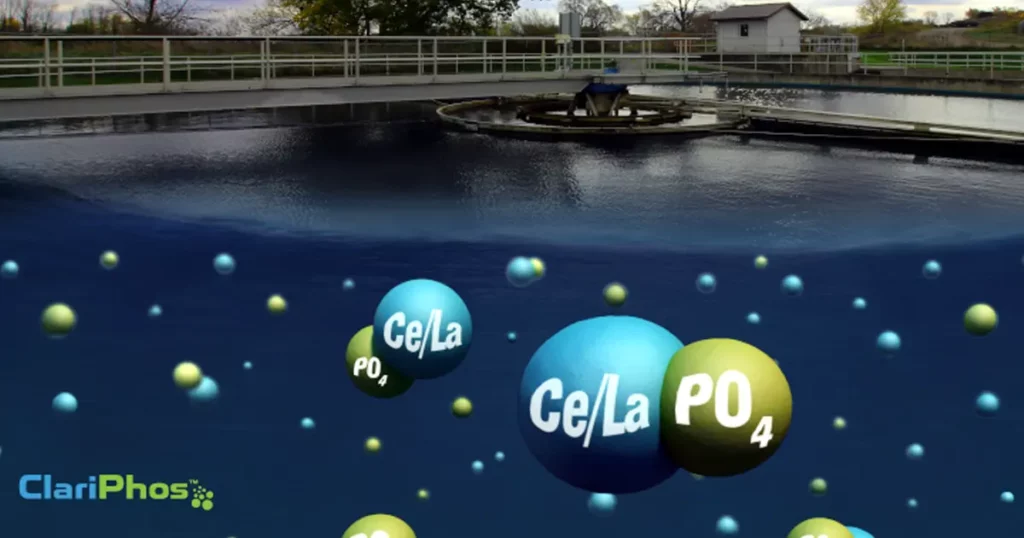

How can a wastewater treatment plant eliminate the need for pH adjustment while also reducing coagulant consumption? The answer lies in switching to a coagulant that is less acidic and achieves removal targets at lower dose rates than alternatives: ClariPhos® Rare Earth Coagulant.

Here’s how it works.

ClariPhos is 100x less acidic than alternatives

Conventional aluminum- and iron-based coagulants are highly acidic and their use can consume alkalinity and lower the pH of the wastewater system. Highly alkaline chemicals are often added to maintain alkalinity and pH in the optimal ranges, or to comply with discharge limits. However, pH adjustment chemicals are costly and also pose risks to operators and equipment because of their extreme causticity.

ClariPhos, made with the rare earth elements cerium and lanthanum, is about 100 times less acidic than many conventional coagulants. It also has a high affinity for phosphorus and can achieve ultra-low phosphorus targets at significantly lower dose rates than others.

Immediate results with long-lasting benefits

An extended aeration wastewater plant in Ontario experienced the advantages of ClariPhos after switching coagulants. The plant was receiving an average influent flow of about 1,000 m3/day and was adding a polyaluminum chloride (PAC) coagulant for phosphorus removal and sodium hydroxide for pH control.

Once ClariPhos treatment began, operators were able to stop pH adjustment soon afterwards. ClariPhos dosing is typically higher during the transition period and then gradually reduced to the optimal rate.

A single bulk delivery of ClariPhos will now provide a full year’s supply of coagulant for the plant compared to multiple deliveries of PAC and sodium hydroxide. With fewer deliveries, the site can also benefit from reduced shipping costs and avoid the risks of repeatedly handling large volumes of chemicals.

ClariPhos enabled the WWTP to maintain pH within the required range without the addition of sodium hydroxide and at a significantly lower coagulant dose rate. The graph above compares the dose rates of both treatment programs during 2024.

Savings were also realized in equipment and maintenance. Operators can now spend more time on other tasks since they no longer have to periodically replace caustic feed lines or rebuild the diaphragm pumps – costly annual chores.

A seamless transition with dedicated support

Switching to ClariPhos was simple. Bishop Water technicians performed jar testing to demonstrate ClariPhos dosing and performance compared to PAC. The plant was also assessed to ensure that the existing systems could accommodate the new coagulant without modification. Regular site visits and monitoring by Bishop Water technicians optimized dosing as residual PAC in the system was gradually depleted. Throughout the transition, the plant maintained compliance with its discharge limit of 0.15 mg/L total phosphorus, pH and alkalinity.

Learn more about ClariPhos Rare Earth Coagulant