ARTICLE

Bishop Water completes water treatment project at industrial lagoon to remove metals, PCBs

The challenge: Onsite treatment of highly contaminated industrial water

The environmental remediation of a two-hectare industrial lagoon in Port Hope, Ontario, was an important project to restore the natural features of the property and enable safe use by the community. The water stored in the lagoon was severely impacted by industrial waste, with elevated levels of heavy metals, PAHs, PCBs, and semi-volatile organics that exceeded the Provincial Water Quality Objectives (PWQO).

Over 15,000m³ of contaminated water would need to be pumped out of the lagoon and treated before the hazardous sediments could be removed.

The solution: A multi-stage water treatment system

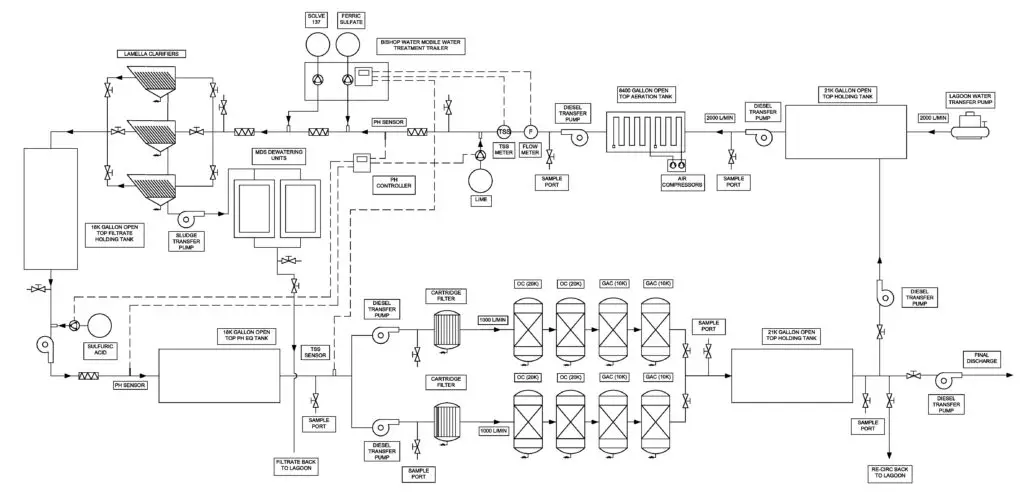

To tackle the water treatment challenges, Bishop Water designed, installed and operated a multi-stage, advanced portable wastewater treatment system (PWTS) that was capable of processing up to 1,156 litres per minute. The system included several steps to address suspended and dissolved contaminants. The major components included aeration, pH adjustment, coagulation, flocculation, clarifiers, sand filters, organoclay vessels, granular activated carbon vessels and Geotube containers to collect and dewater polymer-conditioned sludge.

Bishop Water worked closely with the consulting engineer and the site owner during the early stages of the project to perform bench testing with water samples from the site and develop the optimized treatment processes.

The results:

Once commissioned, the system operated on site for about six months, from May to October. During that time, the Bishop Water team operated the system, monitored treatment performance and recorded all performance metrics for environmental reporting. The team also responded to changing influent characteristics which were experienced as the water level was lowered and the deeper water, with higher concentrations of contaminants, was pumped to the treatment system.

As the water warmed, algae also became an operational issue that required more frequent backwashing of the filter media. Bishop Water technicians were able to overcome the problem by switching coagulants from ferric sulphate to ClariPhos® Rare Earth Coagulant. This improved algae removal, reduced backwashing and eliminated concerns about iron residuals in treated effluent. Cartridge filters were also added to capture fine particulates and prevent algae from entering the adsorption media.

Over 15,000 m³ of contaminated water was successfully treated and removed from the site, significantly advancing the project and enabling sediment removal to occur afterwards.

Contact us to discuss a water treatment solution for your remediation project or industrial site.