CASE STUDY

Simplifying arsenic sludge management at a gold mine

The challenge:

Efficiently and cost-effectively managing sludge from contaminated groundwater treatment

In 2016, an underground gold mine in Western Canada installed a mobile microfiltration (MF) system to remove arsenic from groundwater that is pumped from the shafts. The system operates 24-hours per day since water is constantly percolating through the rock and becoming contaminated with arsenic as it contacts the naturally occurring element.

During spring thaw, the rate of water infiltration can rise as high as 1,000 L/min and arsenic levels can exceed 500 ppb.

As the water is pumped out, ferric chloride is added to precipitate the arsenic before filtration. However, the high arsenic concentration requires large doses of ferric chloride and produces a significant amount of sludge.

Consequently, the MF system needs to be backwashed about every 45 minutes and produces approximately 1,900 liters of sludge each time.

The high volume of sludge was challenging to manage with an existing media filtration system.

The site needed a faster, more reliable and more cost-effective way to separate and dewater the solids and ensure the final effluent met provincial regulations for discharge to a nearby creek.

Two Geotube containers are set up in roll-off bins to collect and dewater the arsenic sludge. Once full, operators can easily move the bin to an onsite storage area, tip out the Geotube then quickly replace it with a new one.

The Bishop Solids Management Solution has been operating alongside of the MF system since 2016, providing operators with a simple, reliable way to manage the backwash sludge and continually meet discharge requirements for arsenic.

The solution:

A compact, easy-to-operate system improves sludge collection and dewatering

Bishop Water installed its Mobile Solids Management Solution, a simple, low-energy process that uses Geotube® containers, polymers and gravity to collect and dewater the arsenic sludge.

The compact system operates inside the mine’s mill building and provides reliable performance with little operator oversight.

About every 12 hours, accumulated sludge is pumped from an 88m3 mix tank to one of two Geotube containers that are set up inside roll-off dewatering bins.

As the sludge is pumped, Bishop Water’s non-mechanical VEPAS (Venturi Emulsion Polymer Activation System) adds the optimal dose of polymer directly into the feed line to accelerate dewatering and retain solids.

The automated VEPAS eliminates mixers and aging tanks, making the polymer system easy to use and maintain.

Clear filtrate is released from the pores of the Geotube and is pumped to another tank for testing prior to release. An operator verifies that the arsenic level of the filtrate is below the regulatory limit of 10 ppb (0.01 mg/L) before it is released to a pond that empties into a creek.

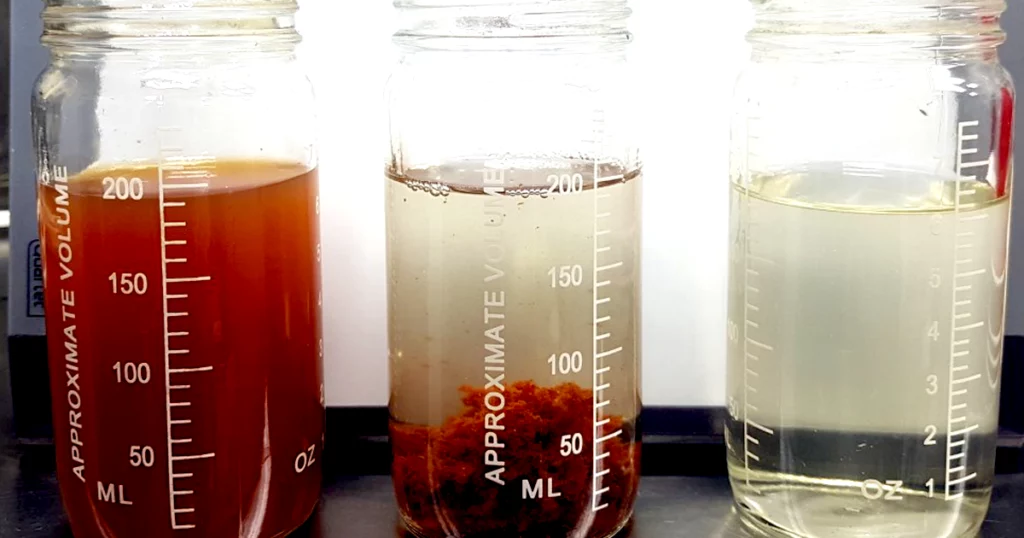

Jar testing shows the results of the simple, low-energy Bishop Solids Management Solution. From left: A sample of the sludge backwash from the MF system; solids clump together after polymer addition; clear filtrate is released from the Geotube container.

The results:

Simple process for management and disposal of arsenic sludge

The Bishop Solids Management Solution has been operating alongside of the MF system since 2016, providing operators with a simple, reliable way to manage the backwash sludge and continually meet discharge requirements for arsenic.

The Geotubes accept sludge as quickly as it is pumped in and provide dewatering, filtration and containment in a single step.

Once a Geotube container is full, it is transported in the roll-off bin to an area in the tailings facility where it is left for permanent storage. After dumping the Geotube container, the bin is returned to the mill and the bag is easily replaced.