Geotube® Shoreline Protection

Geotube® for shoreline protection

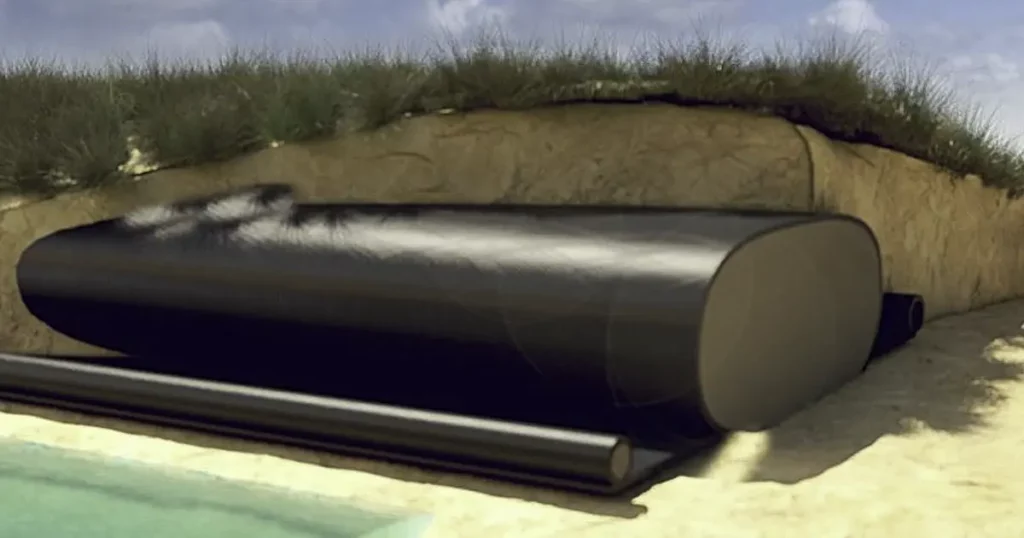

How Geotube systems for shoreline protection combat rising water levels, higher waves and more frequent and intense storms that are impacting shorelines along coastal areas and inland waterways.

Reliable, resilient, shoreline protection.

Coastal shorelines and inland waterways are increasingly impacted by rising water levels, higher waves and more frequent and intense storms. Many of these areas are experiencing serious erosion that is threatening property, infrastructure and natural environments.

Geotube® geotextile systems have been used for over 50 years in a broad range of challenging applications including:

- Shoreline protection

- Wetlands restoration

- Beach nourishment

- Flood protection

- Jetties and causeways

- Underwater structures

The Advantages of Geotube Shoreline Protection

Virtually immovable mass

A single Geotube® container is more than 100 feet long and when filled with sand could weigh up to 150 tons. With that much mass, it becomes extremely difficult for waves, debris and ice to shift the Geotube® container. Containers are typically about seven feet wide or more, which enables a wider protection structure that can be constructed much more quickly and at lower cost than conventional rock, timber or steel barriers.

Deflective elliptical shape

As debris or ice advances towards the shoreline, the elliptical shape of the Geotube® containers can deflect the material and force it up and over the structure. Conventional barriers made of materials such as armour stone or timber face the ice head-on and are often dislodged or heaved up.

Durable, impact-resistant technology

Geotube® containers are specially designed for shoreline protection and are manufactured using high-strength polypropylene multifilament yarns that meet several ASTM standards for fabric strength, seam strength, UV resistance and puncture resistance. In extremely demanding applications, Geotube® containers can be further protected with a Geotube® Debris Shield, a polyurea coating, or even a conventional barrier such as an armour stone wall.

Versatility and customizability

Geotube shoreline systems are available in several configurations and sizes. Each one is designed to provide maximum performance, lifespan and ease of installation. Many can also be custom manufactured to meet site specifications.

Fast and easy to install

Geotube containers are filled in-place with a slurry mix of sand and water or locally dredged material. This simple process enables Geotube® containers to be installed much more quickly than conventional approaches such as armour stone or concrete. Once filled and installed, Geotube® containers with crimpled fibers enable soil to become entrapped and help establish vegetation that can further stabilize landscape as part of a “living shoreline” approach.

Speak with an expert

Contact us today to discuss a simple, low-energy solution for your site.

Download the brochure

RELATED SOLUTIONS

Bishop Solids Management Solution

Reduce the cost and complexity of solids collection, dewatering and containment with easy-to-operate, low-energy Bishop Solids Management Solutions.

Sludge dewaterability testing

Simple, bench-scale tests can quickly and accurately model the performance and anticipated savings of full-scale Bishop Solids Management Solutions.

ClariPhos Rare Earth Coagulant

With this advanced coagulant, wastewater treatment plants can achieve ultra-low phosphorus limits—as low as 0.07 mg/L—without the need to install or upgrade costly tertiary filtration systems.